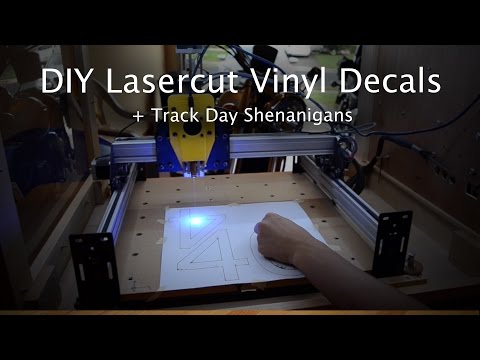

I took my car to the track, so I laser cut some vinyl numbers for my car. No, I did not skip project #39… that is coming later.

Removable Vinyl Sheets I used: http://amzn.to/1Jpo4mc

Laser Module: LaserInk (2 Watt, Developmental Prototype)

As noted in the comments, it’s always a good idea to check your work material’s decomposition products before proceeding.

Judging by the fct your at NJMSP in millville, Nj; what I can make out of your plates on your car; and how you pronounced "y'all" I take it your a fellow South Jersian? You videos have helped me a lot, and were the deciding factor to go with a Shapeoko 3 as my net mill. Thanks and hope to run into you one day down here.

Its my understanding vinyl and PVC inyl and PVC produce a corrosive gas – both contain chlorine regardless if you only cut it once.

always be very careful what you cut with a laser cutter. Even having some air and open ventilation the chlorine gas emitted when cutting normal vinyl will be very bad for your machine (and you).

Would toxic vinyl textile cut with this laser? ¿Burn edges? Are edges is yellowish?

Will this work with heat transfer vinyl for heat press?

food for thought: i used to put the vinyl numbers to a magnet sheet that can be reused over and over.

Winston, Can you supply a parts bill of materials and instructions on how to convert the Shapeoko-3 to the laser rig you show in this video? I want to convert a second Shapeoko to a laser unit and this looks like a great way to go.

Anyone else out there that have a good later rig up? Please comment to me at derfleznew@yahoo.com. Thanks.

awesome video, man!!!

Hi Winston, cool project! I always really enjoy your videos. Vinyl decals are typically cut using a vinyl cutter — you can see one in action in my "Word Clock" video if you are interested.

I'm thinking that modifying a Shapeoko to have a cutting tool attachment could make for an interesting project video…

Winston,In my day job I work on a laser inline with a press. Anyway to our knowledge there are no laser cuttable vinyls, they do emit gases

that are a health hazard. There is a European vinyl that is laser cuttable but a bit pricey . If you want to do vinyl I might suggest a drag knife

Great Video, I enjoyed riding with you both days!

Lol mini van

Instead of cutting into the corner, and then out, where the laser spends a lot of time, cut out from the corner in both directions. This should allow the material to cool, and prevent flare up on the 2nd cut.

Woo! Lasers! Are you using a standard g-code generator in maker cam or just the plugin via Inkscape? I am building a huge 5.6w laser and using Grbl to drive it.

I found it very interesting – I used to be on a pit crew for a road track team so I liked it – good job man

Hi Winston! Great job as usual! I also have a SO2 and wonder which laser you've been using on your machine.

As an alternative to a laser (chlorine gas bad) I wonder how well a drag knife would work (work holding would be interesting).

If you want easier application, you can use transfer paper. A sticky paper that holds your design in place between removing the backing and applying the decal.

Simply cut your vinyl, weed the waste away, apply transfer paper to the top, then peel away the non-stick backing. Next you just apply the vinyl numbers that are attached to the transfer paper and then peel the transfer paper off. It helps prevent vinyl distortion and would have made your "not found" application a piece of cake!

You might want to do a copper wire test on the vinyl to see if it contains chlorine. If it does, laser cutting it will generate hydrochloric acid and chlorine gas. One of which is bad for your machine and the other is bad for you.