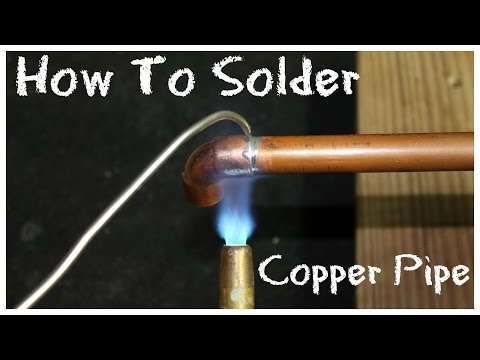

Check out this video to learn some basic soldering skills that can be utilized in so many ways around your homestead. Adding new sinks, fixing leaks, repairing hose bibs, adding new hose connections, upgrading water supply lines, building a boiler, additions, new home construction, and so many more! In past experience I worked as a residential heating and cooling installer and learned so many valuable skills from that job. Although I did not make it a career I can take what I learned there and apply it to our homestead moving forward. Throughout our journey to becoming more self sustaining and self reliant I will be sharing any of these basic skills that I feel may benefit someone else out there looking to do some of these very same things.

Being able to repair your own plumbing and install new plumbing fixtures is a skill I think that every home owner should know. It starts with picking up a few basic tools that you will never regret getting. I have a list of some of the items that I use at the bottom of this article. A good torch, pipe and fitting cleaner, solder, and flux is about all you really need to get started. Once you have what you need grab a few scrap pieces of copper pipe and a few fittings and solder a couple of joints following this video. You will quickly be able to get the hang of it and be ready to take on any repair or plumbing project in your home.

In an upcoming article/video I will be installing a utility tub in our basement and running the water supply lines. We are getting ready to have a place to clean fish and also handle other cleanup from various projects around the homestead. I was surprised when we moved into this house that there was no utility tub in the laundry area or basement and I have finally gotten a chance get one put in.

I hope that this video has encouraged you to take on some of your own plumbing projects and as always please let me know if you have any questions!

Spark start torch head – http://amzn.to/1BMl54f

Mapp Gas cylinder – http://amzn.to/14G5DdF

1/2″-3/4″ pipe and fitting cleaner combo tool – http://amzn.to/1BSy2ao

Tight spaces pipe cutter – http://amzn.to/1y0INKD

Pipe cutter – http://amzn.to/1xP2qDj

Lead free solder – http://amzn.to/1wGPqvL

Flux – http://amzn.to/1yPxXqA

All of these products and more recommended items from the SSL Family are available at the Simple Suburban Living General Store – http://astore.amazon.com/simpsubulivi-20

For more information and other sustain projects and how to’s please visit www.simplesuburbanliving.com

Follow us on……

http://www.pinterest.com/simplesuburban/

http://www.facebook.com/simplesuburbanliving

http://www.twitter.com/simplesuburban5

http://www.instagram.com/simplesuburbanliving

Music – “River Went Dry” by Josh Woodward. Free download: http://joshwoodward.com/song/RiverWentDry

Thanks a lot man!

Good job. Is there a rule of thumb for how much solder you use for the various diameter of tube?

Can you just put solder around joints that are leaking without cleaning them. Just putting new solder over the old. Thanks

How to basic? No eggs?

This is Awesome ! Thank You

Attention to detail. Love it.

Good Video dude only pointer when your soldering you need to ensure that there is pipe in both ends of the fitting otherwise when you come to solder the other end the solder will not run correctly causing a leak which nobody wants haha also i was taught never apply flux inside the fitting because the more acidic fluxes aka laco will eat through the pipe causing it to pinhole not to bad if you can flush the system out but on gas pipework its a big no no 🙂

Thank you for this video!

you never reemed the pipe new guy

Nice to see a job done properly.

At 7:09 you mention that you want to try and keep the elbow at an angle while soldering. What is the benefit of soldering it at an angle? Thanks for the great video.

GREAT Video! I'm very New to soldering copper! If I want to join two copper sheets (approx. 1/16" thick) would I need to SOLDER or BRAZE for a structural joint? I'm interested in learning this from an artistic standpoint. I would appreciate ANY help or information! Thanks In Advance! Have A Super Week!…..Gus